Residual medicines and additives are vomited from the inside of precision stamping parts, and the tin layer attached to the plating is easily corroded by these substances. It causes surface oxidation and yellowing of the coating. Inadequate treatment and no drying of the workpiece can also lead to yellowing of the coating. Adhesion of tetravalent tin, excessive additives, zinc impurity pollution in bath (less likely), insufficient thickness of coating, iron impurity pollution (phenomenon is not easy to find in the process of plating) and storage environment. These are the reasons that lead to yellowing of precision metal stamping parts.

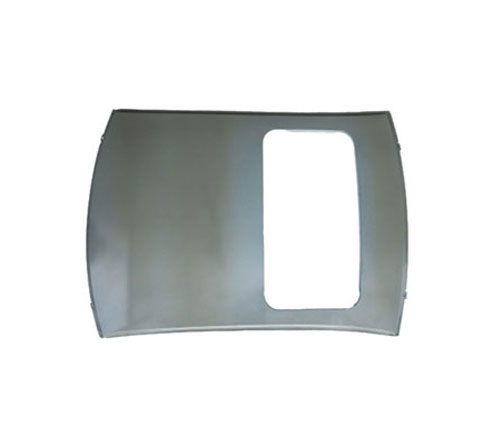

Automobile stamping parts

Die is an indispensable process equipment in stamping process. It plays an important role in product quality, prolonging product life and production efficiency. It is difficult to meet the production demand because of the wear and tear of the die in the production process and the loss of working size. Therefore, it is very important to improve the durability of the die.

Surface treatment of automotive stamping parts refers to the process of forming an overlay by processing the surface of the parts in some way. The main purpose is to make the surface of the workpiece beautiful, anti-

corrosion effect, etc. There are several surface treatment methods.Electroplating: Plating parts are immersed in an aqueous solution containing deposited

metal compounds, and the electroplated metal is precipitated and deposited on the parts by current passing through the plating solution. Generally, galvanizing, copper, nickel, chromium, copper-nickel alloy, etc.

Oxidation treatment: can be divided into chemical oxidation and anodic oxidation.

Price of automobile stamping parts

Passivation treatment: pure iron and pure aluminium react in concentrated sulfuric acid or nitric acid. The atoms on the surface react with acid to produce a dense oxide film, which prevents the internal substances from reacting with concentrated acid to achieve protection.

Electrophoresis: Paint is coated on the surface of material under the action of external current. It is characterized by rich color, poor adhesion and difficult to control uniformity of color.

Mechanical plating: The surface of the product is impacted by the particles of the coated metal, and the coatings are cold welded to the surface of the precision stamping parts.

Automotive stamping parts manufacturer

There are several ways to improve the durability of dies:

Improve the design of stamping die, select the material of stamping die correctly, forge and heat treatment the parts of stamping die reasonably, arrange the manufacturing process of stamping die reasonably and ensure the processing accuracy, select the press correctly, use and maintain the stamping die reasonably. Above are several tips commonly used to improve the wear resistance of precision stamping dies. The improvement of wear resistance can not only prolong the service life of the die, but also reduce the production cost of the die. It also ensures the quality of the products manufactured and improves the production efficiency.

Copyright By © Jiangsu Halreal Vehicle Industry Co., Ltd. 技术支持:翊成网络